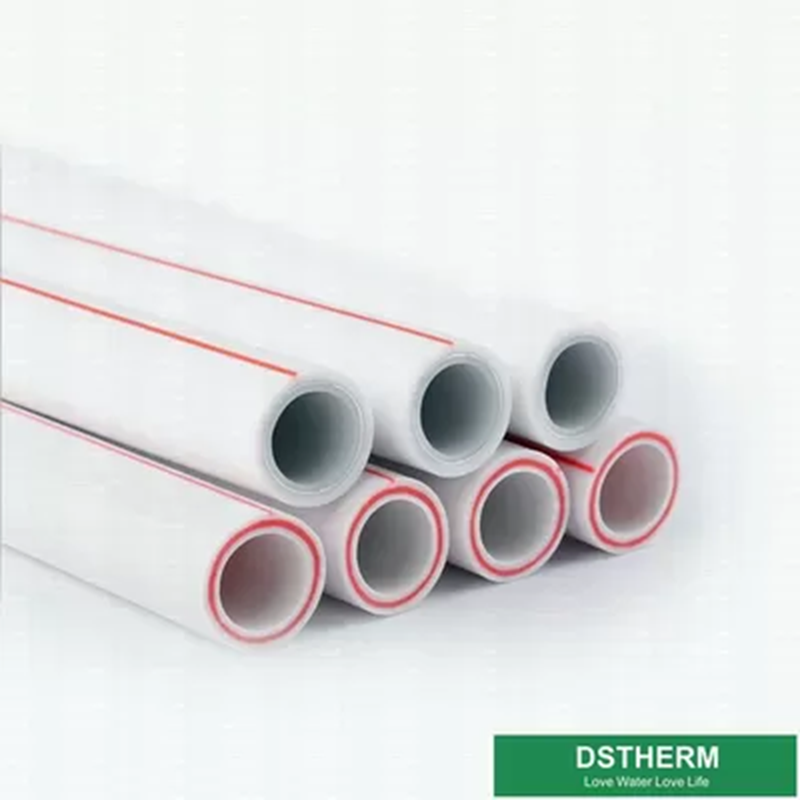

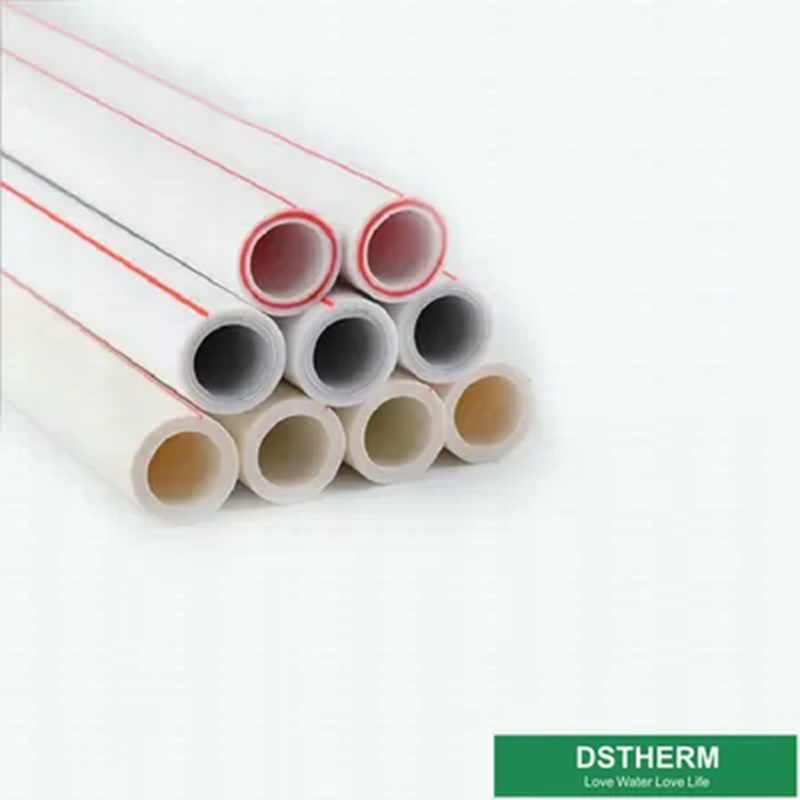

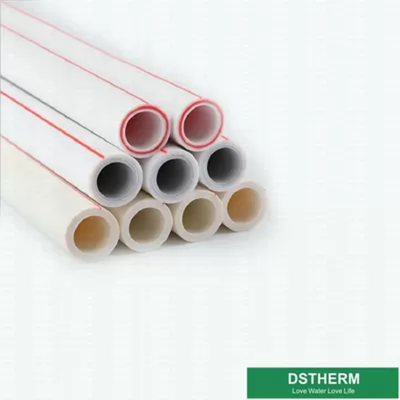

PPR Fiberglass Composite Pipe

Hot Melting PPR Fiberglass Composite Pipe Heat Preservation For Food Industry Pipeline

- Place of Origin:Zhejiang China

- Brand Name:DSTHERM

- Certification:ISO9001

- Model Number:20-160mm

- Product description: Ppr pipe, Ppr Fittings, Plastic ppr pipe, plastic pipe, tube,pprct pipe, pprct fittings, Ppr Aluminum pipe, Ppr-Al-Ppr pipe, Ppr Fiber Pipe, Ppr Uv Pipe, Ppr perforated pipe, Ppr stop valve, Ppr Ball

Hot Melting PPR Fiberglass Composite Pipe Heat Preservation For Food Industry Pipeline

Payment & Shipping Terms

PPR Fiberglass Composite Pipe ISO9001 DIN8077/8078 Color customization size 20-160

PP-R Fiber Composite pipe

OEM Available

Material: PPR HYOSUNG R200P from Korea,

Standard: ISO 15874: DIN8077-8078

Production temperature: -40 - +95°C

Pressure Rating: PN10,PN12.5,PN16 ,PN20

Connection:socket fusion joint,electro fusion joint or transition joint

|

|

PN 1.25MPa | PN 1.6MPa | PN 2.0MPa | PN 2.5MPa |

|

Outer Diameter dn(mm) |

Wall Thickness en(mm) |

Wall Thickness en(mm) |

Wall Thickness en(mm) |

Wall Thickness en(mm) |

| 20 | 2.0 | 2.3 | 2.8 | 3.4 |

| 25 | 2.3 | 2.8 | 3.5 | 4.2 |

| 32 | 3.0 | 3.6 | 4.4 | 5.4 |

| 40 | 3.7 | 4.5 | 5.5 | 6.7 |

| 50 | 4.6 | 5.6 | 6.9 | 8.4 |

| 63 | 5.8 | 7.1 | 8.7 | 10.5 |

| 75 | 6.9 | 8.4 | 10.3 | 12.5 |

| 90 | 8.2 | 10.1 | 12.3 | 15.0 |

| 110 | 10.0 | 12.3 | 15.1 | 18.3 |

| 160 | 14.6 | 17.9 | 21.7 | 26.6 |

| Items | Index | ||

| Pipe Material | Pipe Article | ||

| Density | G/cm³20℃ | 0.89-0.91 | |

| Heat Transmitting Index | W/m.k(20℃) | 0.23-0.24 | |

| Thread Expand Index | Mm/m.k | 0.14-0.16 | |

| Flip Thread Mode Mete | W/m²(20℃) | 800 | |

| Extend Intendity | Mpa | More than 20 | |

| Minitication in Portrait | 135℃, 2h% | Less than 2 | |

| Swing and Beat Impact Test | 15J, 0℃, 2H (disrepair rate)% | Less than 10 | |

Advantages:

High temperature resistance: the maximum sustained working temperature is up to 70°Cdegrees, the maximum transient temperature is up to 95°C

Heat preservation: low thermal conductivity results in preserving heat

Non-toxic: no heavy metal additives, would not be covered with dirt or contaminated by bacterium

Lower installation costs: light weight and easy installation can reduce installation costs

Higher flow capacity: smooth interior walls result in low pressure loss and high volume

Feature

1. Sanitary & non-toxic;

2. Corrosion resistant & not scaling;

3. High temperature resistant & high pressure resistant;

4. Heat preservation & energy efficient;

5. Light weight;

6. Elegant appearance;

7. Convenient & reliable installation;

8. Long service life: over 50 years

Applications:

1 ) Cold, hot water supply facilities for public buildings

2 ) Food, chemical, electronic industrial pipeline networks such as pipeline networks for transporting all kinds of corrosive liquid (such as acid, buck and deionized water )

3 ) Drinking water production system pipeline networks such as pure water and mineral water

4 ) Air conditioning facility pipeline

5 ) Compressed gas pipeline networks for industry

6 ) Pipeline network for swimming pool

7 ) Pipeline network for solar energy facility

8 ) Agriculture and garden production transporting system

We can supply products of different colors as per customer's request.

Categories

- Plastic Ppr Pipe

- PPR Aluminum Pipe

- PPR Fiberglass Composite Pipe

- PPR Pipe Fittings

- PPR Double Union Ball Valve

- PPR Stop Valve

- Brass Insert

- Plastic Pipe Cutter

- PEX Tubing

- Brass Fittings

- Brass Compression Fittings

- Garden Hose Pipe Fittings

- Brass Flared Fittings

- PEX Brass Fittings

- Brass Ball Valve

- Brass Gate Valve

- Brass Bibcock

- Brass Angle Valve

- Brass Thermostatic Valve

- Water RO Purifier

Latest News

Contact Us

Contact: Kathy Zhang

Phone: 13361988316

Tel: +86 21 51316758

Add: No.80 Tian Gong Road Shanghai China

Johnsonyuan

Johnsonyuan