PPR Aluminum Pipe

Plastic Composite Fiberglass Ppr Pipe Pn25 50mm Ppr Aluminum Composite Pipe 50mm For Heating System

- Place of Origin:Zhejiang China

- Brand Name:DSTHERM/OEM/CUSTOMIZED

- Certification:ISO9001/ISO15874/AENOR

- Model Number:20mm 25mm 32mm 40mm 50mm 63mm 75mm 90mm 110mm

- Product description: Ppr pipe, Ppr Fittings, Plastic ppr pipe, plastic pipe, tube,pprct pipe, pprct fittings, Ppr Aluminum pipe, Ppr-Al-Ppr pipe, Ppr Fiber Pipe, Ppr Uv Pipe, Ppr perforated pipe, Ppr stop valve, Ppr Ball

Plastic Composite Fiberglass Ppr Pipe Pn25 50mm Ppr Aluminum Composite Pipe 50mm For Heating System

Payment & Shipping Terms

Description

Plastic Composite Fiberglass Ppr Pipe Pn25 50mm Ppr Aluminum Composite Pipe 50mm For Wall Heating System

PPR Fiberglass Composite Pipe

PPR Fiberglass reinforced multilayer composite pipes

Are you searching for PPR Fiber Glass Composite Pipe Suppliers for your industrial plumbing applications? Then look no further, DSHTERM is the most massive Industrial PPR pipes and fittings Supplier in China market. We have the products & expertise that can meet your requirements.

PPR Fiber Glass Pipe DSTHERM

DSTHERM Fiber-G (PPR/Fiberglass/ PPR) composite pipes :DSTHERM Fiber-G polymer composite pipes produced by multi-extrusion method with middle layer made of special polymer-fiberglass composition, which was specially designed in the laboratory of Blue Ocean plant.

Glass Fiber Reinforces Fiberglass Composite Pipes ISO9001 DIN8077/8078 Color customization size 20-160

PP-R Fiber Composite pipe

OEM Available

Material: PPR HYOSUNG R200P from Korea,

Standard: ISO 15874: DIN8077-8078

Production temperature: -40 - +95°C

Pressure Rating: PN10,PN12.5,PN16 ,PN20

Connection:socket fusion joint,electro fusion joint or transition joint

| PN 1.25MPa | PN 1.6MPa | PN 2.0MPa | PN 2.5MPa | |

|

Outer Diameter dn(mm) |

Wall Thickness en(mm) |

Wall Thickness en(mm) |

Wall Thickness en(mm) |

Wall Thickness en(mm) |

| 20 | 2.0 | 2.3 | 2.8 | 3.4 |

| 25 | 2.3 | 2.8 | 3.5 | 4.2 |

| 32 | 3.0 | 3.6 | 4.4 | 5.4 |

| 40 | 3.7 | 4.5 | 5.5 | 6.7 |

| 50 | 4.6 | 5.6 | 6.9 | 8.4 |

| 63 | 5.8 | 7.1 | 8.7 | 10.5 |

| 75 | 6.9 | 8.4 | 10.3 | 12.5 |

| 90 | 8.2 | 10.1 | 12.3 | 15.0 |

| 110 | 10.0 | 12.3 | 15.1 | 18.3 |

| 160 | 14.6 | 17.9 | 21.7 | 26.6 |

| Items | Index | ||

| Pipe Material | Pipe Article | ||

| Density | G/cm³20℃ | 0.89-0.91 | |

| Heat Transmitting Index | W/m.k(20℃) | 0.23-0.24 | |

| Thread Expand Index | Mm/m.k | 0.14-0.16 | |

| Flip Thread Mode Mete | W/m²(20℃) | 800 | |

| Extend Intendity | Mpa | More than 20 | |

| Minitication in Portrait | 135℃, 2h% | Less than 2 | |

| Swing and Beat Impact Test | 15J, 0℃, 2H (disrepair rate)% | Less than 10 | |

Advantages:

High temperature resistance: the maximum sustained working temperature is up to 70°Cdegrees, the maximum transient temperature is up to 95°C

Heat preservation: low thermal conductivity results in preserving heat

Non-toxic: no heavy metal additives, would not be covered with dirt or contaminated by bacterium

Lower installation costs: light weight and easy installation can reduce installation costs

Higher flow capacity: smooth interior walls result in low pressure loss and high volume

Feature

1. Sanitary & non-toxic;

2. Corrosion resistant & not scaling;

3. High temperature resistant & high pressure resistant;

4. Heat preservation & energy efficient;

5. Light weight;

6. Elegant appearance;

7. Convenient & reliable installation;

8. Long service life: over 50 years

Applications:

1 ) Cold, hot water supply facilities for public buildings

2 ) Food, chemical, electronic industrial pipeline networks such as pipeline networks for transporting all kinds of corrosive liquid (such as acid, buck and deionized water )

3 ) Drinking water production system pipeline networks such as pure water and mineral water

4 ) Air conditioning facility pipeline

5 ) Compressed gas pipeline networks for industry

6 ) Pipeline network for swimming pool

7 ) Pipeline network for solar energy facility

8 ) Agriculture and garden production transporting system

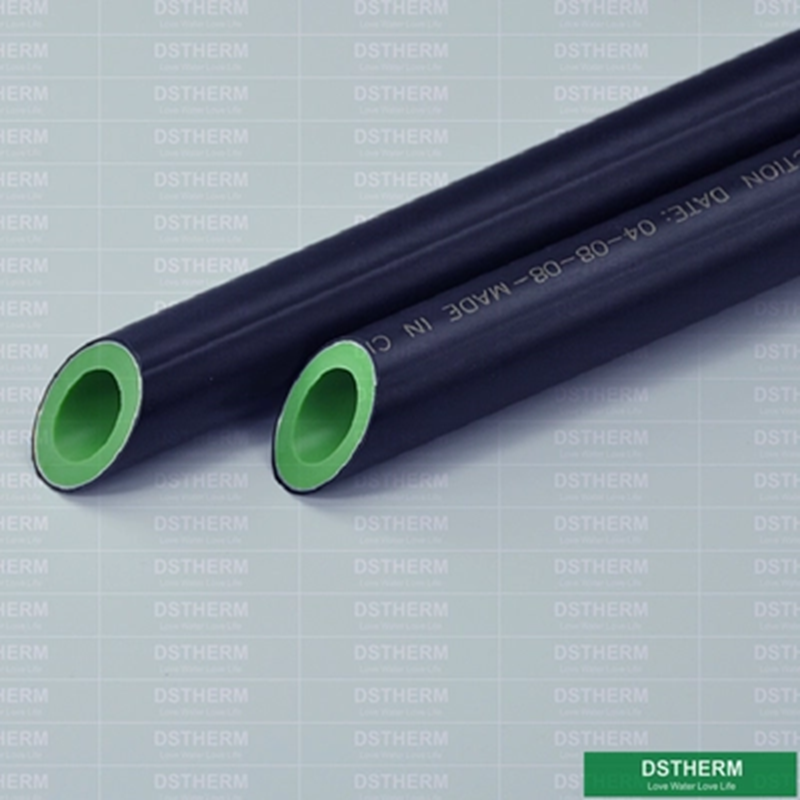

We can supply products of different colors as per customer's request.

What is Ppr Aluminum Pipe? Aluminum-plastic composite PPR pipe is a composite pipe of five layers, inside and outside layers of which are made of PP-R, tightly bonded with melt adhesive to the mid-layer of aluminum core which is longitudinally welded in an overlapping way.

What is Ppr Perforated Aluminum Pipe? Perforated Aluminum-plastic composite PPR pipe is a composite pipe of five layers, inside and outside layers of which are made of PP-R, tightly bonded with melt adhesive to the mid-layer of perforated aluminum core which is longitudinally welded in an overlapping way.

Ppr Composite Aluminum pipe with ppr aluminum-plastic ISO9001 DIN8077/8078 Color customization 20mm-160mm

Product: PP-R Perforated Aluminum Composite pipe

Material: PPR+Aluminum

Size: 20mm 25mm 32mm 40mm 50mm 63mm 75mm 90mm 110mm

Certificate:ISO9001

Standard: ISO15874; DIN8077/8078

Working place: -40°-95°

PP-R Perforated Aluminum Composite pipe

| Series SDR9/S4/PN16 | |||||

|

Nominal Outer Diameter |

Diameter | Wall Thickness | Inner Diameter |

Overall Wall Thickness |

Overall Outer Diameter |

| 20mm | 20.0 | 2.3 | 15.4 | 3.4 | 21.9 |

| 25mm | 25.0 | 2.8 | 19.4 | 4.0 | 27.1 |

| 32mm | 32.0 | 3.6 | 24.8 | 4.8 | 34.1 |

| 40mm | 40.0 | 4.5 | 31.0 | 5.8 | 42.3 |

| 50mm | 50.0 | 5.6 | 38.8 | 6.9 | 52.3 |

| 63mm | 63.0 | 7.1 | 48.8 | 8.4 | 65.3 |

| 75mm | 75.0 | 8.4 | 58.3 | 9.6 | 77.8 |

| 90mm | 90.0 | 10.1 | 70.0 | 11.5 | 93.3 |

| 110mm | 110.0 | 13.7 | 85.8 | 13.7 | 114.0 |

PP-R Perforated Aluminum Composite pipe

PP-R Perforated Aluminum Composite pipe

| Series SDR7.4/S3.2/PN20 | |||||

|

Nominal Outer Diameter |

Diameter | Wall Thickness | Inner Diameter |

Overall Wall Thickness |

Overall Outer Diameter |

| 20mm | 20.0 | 2.8 | 14.4 | 3.9 | 21.9 |

| 25mm | 25.0 | 3.5 | 18.0 | 4.7 | 27.1 |

| 32mm | 32.0 | 4.5 | 23.0 | 5.7 | 34.1 |

| 40mm | 40.0 | 5.6 | 28.8 | 6.8 | 42.3 |

| 50mm | 50.0 | 6.9 | 36.2 | 8.2 | 52.3 |

| 63mm | 63.0 | 8.6 | 45.6 | 10.0 | 65.3 |

| 75mm | 75.0 | 10.3 | 54.4 | 11.5 | 77.8 |

| 90mm | 90.0 | 12.3 | 65.4 | 13.7 | 93.3 |

| 110mm | 110.0 | 15.1 | 79.9 | 16.6 | 114.0 |

PP-R Perforated Aluminum Composite pipe

PP-R Perforated Aluminum Composite pipe

| Series SDR6/S2.5/PN25 | |||||

|

Nominal Outer Diameter |

Diameter | Wall Thickness | Inner Diameter |

Overall Wall Thickness |

Overall Outer Diameter |

| 20mm | 20.0 | 3.4 | 13.2 | 4.5 | 21.9 |

| 25mm | 25.0 | 4.2 | 16.6 | 5.4 | 27.1 |

| 32mm | 32.0 | 5.4 | 21.2 | 6.7 | 34.1 |

| 40mm | 40.0 | 6.7 | 26.6 | 8.0 | 42.3 |

| 50mm | 50.0 | 8.3 | 33.2 | 9.6 | 52.3 |

| 63mm | 63.0 | 10.5 | 42.0 | 11.8 | 65.3 |

| 75mm | 75.0 | 12.5 | 49.8 | 13.8 | 77.8 |

| 90mm | 90.0 | 15.0 | 59.8 | 16.4 | 93.3 |

| 110mm | 110.0 | 18.3 | 73.2 | 19.8 | 114.0 |

PP-R Perforated Aluminum Composite pipe

Applications:

1 ) Cold, hot water supply facilities for public buildings

2 ) Food, chemical, electronic industrial pipeline networks such as pipeline networks for transporting all kinds of corrosive liquid (such as acid, buck and deionized water )

3 ) Drinking water production system pipeline networks such as pure water and mineral water

4 ) Air conditioning facility pipeline

5 ) Compressed gas pipeline networks for industry

6 ) Pipeline network for swimming pool

7 ) Pipeline network for solar energy facility

8 ) Agriculture and garden production transporting system

We can supply products of different colors as per customer's request

PP-R Perforated Aluminum Composite pipe Features:

-

Material: polypropylene and Al

-

Sizes: 20 to110 mm

-

PN Grade: 1.6MPa, 2.0MPa, 2.5MPa

-

Colors: gray or white marked with blue or red lines

-

Connection: socket fusion joint

-

Standard: CJ/T 210-2005, BS6920

-

Certification: ISO9001, ISO14001, OHSAS18001

-

Applications: cold or hot water supply, heating system including flooring heating, wall heating and radiating system, central air conditioning system, industrial liquids transportation

-

Non-toxic: no heavy metal additives, not be covered with dirt, not be contaminated by bacterium

-

Corrosion Resistant: resist chemical matters or electron chemical corrosion

-

Lower Installation Costs: light weight and ease of installation can reduce installation costs by as much as 50% over metal piping system

-

Higher Flow Capacity: smooth interior walls result in lower pressure loss and higher volume than metal pipes

-

Long Life: more than 50 years under proper use

-

Recycled and Environment-friendly

-

Low linear expansion coefficient: it does not curve when transporting hot water for long time

Easy installation and low cost

Good UV-rays and aging resistance makes the pipe has long service life.

Extra Introduction:

Ppr Pipe Introduction: Polypropylene Random plastic type C pipe.

1. What is Ppr Pipe? Ppr Pipe means: Polypropylene Random Copolymer plastic type C pipe.

PPR pipe is type c and a straight and rigid cylindrical pipe, made from Polypropylene Random Copolymer plastic raw mateiral, produced through a continuous extrusion process. They are commonly offered in light green, dark green, blue color, orange color, white color, etc... and in outer diameter sizes ranging from 20mm to 315mm making the pipe walls far thicker according to ISO15874 and DIN8077/8088

2. Ppr Pipe Standard:

ISO15874

DIN8077/8078

3. Color: According to different countries and markets, different customers have different request on the colors, so we have customized Colors, such as Green Color, White Color,bulue color, orange color, dark green clor, etc...

4. Package: DSTHERM Brand Package/ We also accept customer customized brand package with custome logo and descriptions.

5.What are the main use of Ppr Pipe and Ppr Fittings?

PPR Pipe has been growing in popularity over the last couple of years, and rightly so. Its durability, ecological, and economic benefits make PPR pipes one of the best in the industry. That is why most industry leaders have turned to PPR pipes for all their needs.

PPR pipes are commonly used in home installations. It is also used in sanitary liquid, alkaline and acidic solutions, compressed air, and transferring water. But what exactly is PPR pipe, and how is it used? We have prepared this comprehensive guide to help you learn everything about PPR pipes.

What is the PPR Pipe?

First things first, so what exactly is the PPR pipe? Also known as Polypropylene Random Copolymer, PPR pipe is a cylindrical and rigid pipe made from PPR. The pipe is produced through a continuous process known as extrusion. These pipes are usually white or green.

Most PPR pipes have a diameter of 20mm to 110mm. This means that the PPR pipe is thicker than its PVC companions. In addition to that, PPR pipes feature a network of fittings, accessories, and parts. These accessories are available for each PPR pipe diameter.

Like all other pipes, PPR pipes also have their unique properties. These properties set it apart from other pipes. Learn more about PPR pipes characteristics below:

Low Thermal Conductivity

The first thing you should about PPR pipes is that they have low thermal conductivity. This means that external temperatures don’t get to the liquid inside the pipe. Likewise, temperature from the liquid does not escape to the external environment. This is why PPR pipes minimize heat loss or heat gain during the transfer of cold and hot fluids. Using PPR pipes guarantees efficiency and reduced costs

Increased Longevity

PPR pipes can serve you for more than 50 years under varying environmental conditions and a wide range of fluids. What is more, PPR pipes can withstand both cold and hot water systems. To help you understand, PPR pipes can handle the pressure and strain of hot water without breaking. Of course, the premise is that the 50-year life span can only be guaranteed under normal use conditions, such as protecting the pipeline under extreme weather.

Ecological and Economic Efficiency

PPR pipes are easy to transport, cut, and join. These pipes are also easy to use and do not need additional chemicals and materials.

What are the Main Uses of PPR Pipe Fittings?

As you have seen earlier, PPR pipes have several economic, ecological, and durability benefits. This is why these pipes are used in a variety of applications. Keep reading to discover the primary uses of PPR pipe fittings below:

PPR pipe fittings are usually used in the construction of cold and hot water systems. The ability of PPR pipes to withstand both hot and cold temperatures without breaking or cracking makes it the best option for cold and hot water systems. Besides, its low thermal conductivity means that the fluids will retain the required temperature.

PPR fittings are the go-to option for discharging chemical fluids, including industrial waste. PPR piping is the ideal pipe fitting for industries due to its ability to withstand strong chemicals and alkaline solutions.

PPR pipe fittings are also used as purified water supply systems. These pipes are durable and can last for more than 50 years. What is more, they do not break or crack easily even under intense conditions.

The PPR pipes are perfect for a building’s heating system. These pipes can be installed inside floors, radiant, wall heating systems. These pipes can withstand all surfaces and conditions, making them the perfect option for all your heating needs.

PP-R Perforated Aluminum Composite pipe Workshop

Ppr Pipe Applications

1) Cold and hot water supply systems for civil and industrial constructions, e.g. in

residential buildings, hospitals, hotels, school and office buildings, ship building

2) Drinking water systems and food industry pipe works

3) Central air conditioning system

4) Irrigating system for gardens and green houses

5) Public and sport facilities such as swimming pools and stadiums

6) For rainwater utilization systems

Ppr Pipe Advantages:

1, High Temperature Resistance: the maximum sustained working temperature is up to 70 Degrees Celsius, the maximum transient temperature is up to 95 Degrees Celsius.

2, Heat Preservation: low thermal conductivity which is only 1/1500 of brass pipe, and 1/250 of steel pipe.

Non-toxic: no heavy metal additives would not be covered with dirty or contaminated by bacterium.

3, Corrosion Resistant: resist chemical matters or electron chemical corrosion.

4, Lower Installation Costs: light weight and ease of installation can reduce installation costs by as much as 50% over metal piping system.

5, Higher Flow Capacity: smooth interior walls result in lower pressure loss and higher volume than metal pipes.

6, Long Life: more than 50 years under normal conditions.

7, Recycled and Environment-friendly.

Payment term :LC ,TT .

Delivery time : 20days /20 feet container , 35days/40 HQ

Samples lead time: 3-7 days

MOQ: 100-4000pcs

Package: pcs/polybag, 4 meters/tube or as client's request

Ppr Pipe workshop: Polypropylene Random plastic type C pipe.

Ppr Pipe Raw material R200P : Polypropylene Random plastic type C pipe.

Ppr Pipe Series: Polypropylene Random plastic type C pipe.

Ppr Pipe(20mm-160mm)

PP-RCT Pipe(20mm-110mm)

Ppr UV Pipe(20mm-110mm)

Ppr Fiber Pipe(20mm-110mm)

Ppr Composite Pipe(20mm-110mm)

Ppr-Alu-Ppr(20mm-110mm)

Ppr Aluminum Composite Pipe(20mm-110mm)

Ppr Perforated Aluminum Pipe(20mm-110mm)

Ppr-Fiber-Ppr-UV Pipe(20mm-110mm)

Ppr Nano-Antibacterial Pipe(20mm-110mm)

Ppr Copper pipe(20mm-32mm)

Categories

- Plastic Ppr Pipe

- PPR Aluminum Pipe

- PPR Fiberglass Composite Pipe

- PPR Pipe Fittings

- PPR Double Union Ball Valve

- PPR Stop Valve

- Brass Insert

- Plastic Pipe Cutter

- PEX Tubing

- Brass Fittings

- Brass Compression Fittings

- Garden Hose Pipe Fittings

- Brass Flared Fittings

- PEX Brass Fittings

- Brass Ball Valve

- Brass Gate Valve

- Brass Bibcock

- Brass Angle Valve

- Brass Thermostatic Valve

- Water RO Purifier

Latest News

Contact Us

Contact: Kathy Zhang

Phone: 13361988316

Tel: +86 21 51316758

Add: No.80 Tian Gong Road Shanghai China

Johnsonyuan

Johnsonyuan