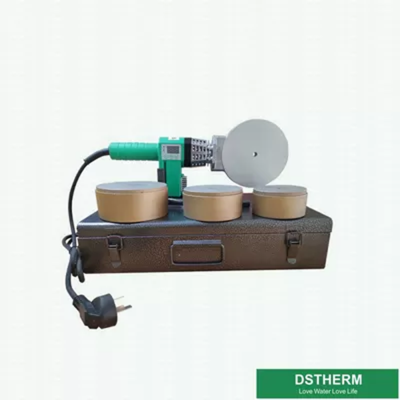

Plastic Pipe Cutter

Socket PPR Welding Device 220V 50Hz Various Dimensions Eco - Friendly

- Place of Origin:Zhejiang China

- Brand Name:DSTHERM

- Certification:ISO9001

- Model Number:20-160mm

- Product description: Ppr pipe, Ppr Fittings, Plastic ppr pipe, plastic pipe, tube,pprct pipe, pprct fittings, Ppr Aluminum pipe, Ppr-Al-Ppr pipe, Ppr Fiber Pipe, Ppr Uv Pipe, Ppr perforated pipe, Ppr stop valve, Ppr Ball

Socket PPR Welding Device 220V 50Hz Various Dimensions Eco - Friendly

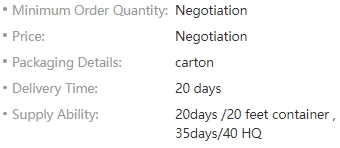

Payment & Shipping Terms

Description

|

|

|||

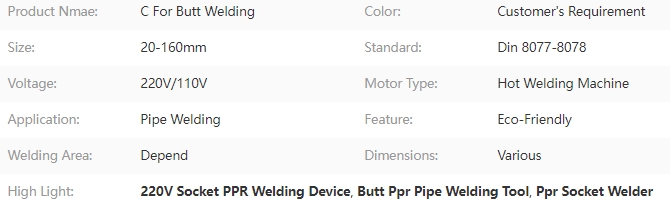

Socket welder for butt welding 220V/110V Color according ISO9001 DIN8077/8078

Technical Parameters:

1. 20-160mm

2. Max. heating plate Temp: 270

3. Working voltage: 220V 50Hz ,110V 60Hz

Technical specifications:

1. This item is suitable for PPR PE,PB pipe material

2. Design with adjustment of temperatures

3. Rated voltage : A C 220/230V 50/60HZ

4. Rated power : 600,800,1200W

5. Working temperature : 200~279 C

6. Ambient temperature :-5C ~45C

7. Other accessories

Application and features:

1. Suitable for socket welding pipes and fittings made of PE or PP.

2. Preprogrammed welding parameter enables to choose the heating time by inputting out diameter of pipe to be welded.

3.The structure design complies with DVS2208.

| Article Number | Size |

| SFD001 | 20-32mm |

| SFD002 | 20-63mm 220V |

| SFD003 | 20-63mm 110V |

| SFD004 | 75-110mm |

| SFD005 |

160mm |

| External diameter | Heating depth | Heat time | Process time | Cool time |

| 20 | 14 | 5 | 4 | 3 |

| 25 | 16 | 7 | 4 | 3 |

| 32 | 20 | 8 | 4 | 4 |

| 40 | 21 | 12 | 6 | 4 |

| 50 | 22.5 | 18 | 6 | 5 |

| 63 | 24 | 24 | 6 | 6 |

How to use

1. Apply die head

Place the welding machine on the stander, chose die head according to pipe’s diameter, and fix it on the machine. In regular, the small end is at the front, the bigger end at the back.

2. Power on

Power on (make sure the power should be with leakage current protector) , the green light and the red light on, wait till the red light off and keep greenlight on, which indicates the machine enter into auto temperature control mode and the machine can be used.

Note: during the auto temperature control mode, the red and the green light will be on and off alternatively, this indicates that the machine is under control and it will not affect operating.

3. Fusion pipes

Using cutter to cut pipe vertically, push the pipe and fitting into die head without any rotation. Take them off immediately when heating time reached (see the table below) and insert

Categories

- Plastic Ppr Pipe

- PPR Aluminum Pipe

- PPR Fiberglass Composite Pipe

- PPR Pipe Fittings

- PPR Double Union Ball Valve

- PPR Stop Valve

- Brass Insert

- Plastic Pipe Cutter

- PEX Tubing

- Brass Fittings

- Brass Compression Fittings

- Garden Hose Pipe Fittings

- Brass Flared Fittings

- PEX Brass Fittings

- Brass Ball Valve

- Brass Gate Valve

- Brass Bibcock

- Brass Angle Valve

- Brass Thermostatic Valve

- Water RO Purifier

Latest News

Contact Us

Contact: Kathy Zhang

Phone: 13361988316

Tel: +86 21 51316758

Add: No.80 Tian Gong Road Shanghai China

Johnsonyuan

Johnsonyuan