PPR Stop Valve

Corrosion Resistant PPR Check Valve High temperature resistance 20-63mm

- Place of Origin:Zhejiang China

- Brand Name:DSTHERM/OEM/CUSTOMIZED

- Certification:ISO9001 & CW617N

- Model Number:20-63mm

- Product description: Ppr pipe, Ppr Fittings, Plastic ppr pipe, plastic pipe, tube,pprct pipe, pprct fittings, Ppr Aluminum pipe, Ppr-Al-Ppr pipe, Ppr Fiber Pipe, Ppr Uv Pipe, Ppr perforated pipe, Ppr stop valve, Ppr Ball

Corrosion Resistant PPR Check Valve High temperature resistance 20-63mm

Description

Corrosion Resistant PPR Check Valve High temperature resistance 20-63mm

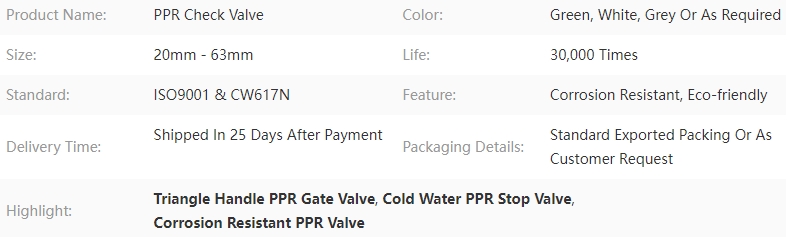

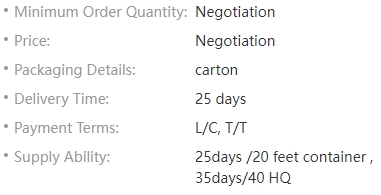

Specification

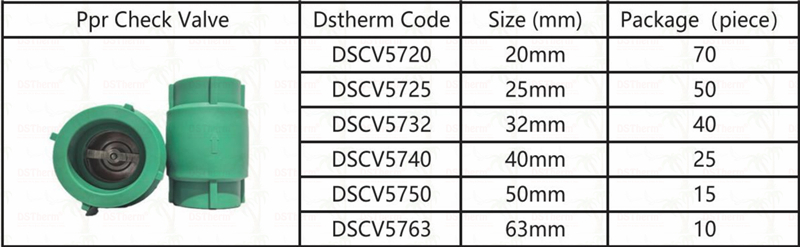

Completed Installation Picture

What is PPR Check Valve?

A PPR check valve is a one-way flow control device made from durable polypropylene random copolymer (PPR), designed to prevent fluid backflow in piping systems. It ensures unidirectional flow, protects equipment (e.g., pumps), reduces water hammer, and maintains pressure stability.

The Function of PPR Check Valve:

-

Prevents Backflow: Ensures unidirectional flow of fluids (e.g., water) to avoid reverse contamination.

-

Protects Equipment: Safeguards pumps, filters, and pipelines from damage caused by reverse flow.

-

Reduces Water Hammer: Minimizes pressure surges or shocks when flow direction suddenly changes.

-

Maintains System Pressure: Stabilizes pressure within the pipeline network.

-

Avoids Pollution: Prevents wastewater or contaminants from flowing back into clean systems.

-

Energy Efficiency: Low-resistance designs optimize flow and reduce energy loss.

DSTHERM PPR Check Valve VS. Market Common Check Valves:

| Comparison Item | DSTHERM PPR Filter Valve | Market Common Check Valves |

|---|---|---|

| Material Composition |

Sealing: EPDM rubber (heat/chemical resistant) Body: Stainless Steel 304 + PPR Fittings: HPb58-3 (lead brass) |

Sealing: Standard rubber or nitrile rubber Body: Brass, cast iron, or PVC Fittings: Generic copper alloy or plastic |

| Lifespan (Cycles) | 30,000 cycles (tested durability) | Typically 10,000–20,000 cycles (standard testing) |

| Pressure Range | Ultra-wide: 0.01–5.0 MPa (covers low-flow to high-pressure scenarios) | Generally 0.1–2.5 MPa (limited applicability) |

| Temperature Tolerance |

Fluid temp: 0–99°C Ambient temp: -10–120°C (stable in extreme environments) |

Fluid temp: Usually ≤80°C Ambient temp: 0–60°C (poor extreme temperature resistance) |

| Additional Features | Integrated filter function (Filter Valve design, reduces need for separate filters) | Only check valve function; requires standalone filters |

| Sealing Technology | Hylosing R200P (proprietary sealing/coating tech, superior leak resistance) | Conventional sealing; prone to leaks due to wear or aging |

| Eco-Friendliness & Safety |

Lead-free Stainless Steel 304 EPDM meets food-grade standards |

Some contain leaded brass/PVC (e.g., HPb58-3) with potential harmful substance release |

| Applications | Industrial high-pressure, high-temperature fluids, chemical media, cold environments (e.g., HVAC, chemical pipelines) | General residential water supply, low-pressure ambient-temperature scenarios |

| Installation & Maintenance | PPR heat-fusion connection, lightweight design, maintenance-free | Threaded/flange connection, requires periodic seal replacement |

This comparison highlights DSTHERM superior performance, reliability, and versatility, making it ideal for demanding industrial and commercial applications.

Physical picture:

Our Advantages:

1. Over 20 Years production experience, Stable &Excellent Quality of our products.

2.Mateial are 100% new raw material, never use recycled material.

3.Sales staffs have 6 -10 years pipe-line system specialized experience,can give the smart and excellent serice and suggestion.

4.Whole product range for pipes,pipe fittings,valves and tools like cutters,welding machines,clamps from 20-160mm all offered.This save your time and costs to collect all items from different suppliers.

5.After-sale service: 24hrs online consultation after-sales,and we accept all conditons for compensation if there any quality issue.

6.we assure our pipes and fittings with 50 years usage life If any quality problem,we agree to accept client's all the claims for compensation.

7.Certifications:CE,ISO

8.OEM Accepted

We will be your the better choice!

Categories

- Plastic Ppr Pipe

- PPR Aluminum Pipe

- PPR Fiberglass Composite Pipe

- PPR Pipe Fittings

- PPR Double Union Ball Valve

- PPR Stop Valve

- Brass Insert

- Plastic Pipe Cutter

- PEX Tubing

- Brass Fittings

- Brass Compression Fittings

- Garden Hose Pipe Fittings

- Brass Flared Fittings

- PEX Brass Fittings

- Brass Ball Valve

- Brass Gate Valve

- Brass Bibcock

- Brass Angle Valve

- Brass Thermostatic Valve

- Water RO Purifier

Latest News

Contact Us

Contact: Kathy Zhang

Phone: 13361988316

Tel: +86 21 51316758

Add: No.80 Tian Gong Road Shanghai China

Johnsonyuan

Johnsonyuan