PPR Pipe Fittings

Casting Metal HDPE Ppr Pipe Clamp Fittings Corrosion Resistant

- Place of Origin:Zhejiang China

- Brand Name:DSTHERM

- Certification:ISO9001/DIN

- Model Number:20mm 25mm 32mm To 315mm

- Product description: Ppr pipe, Ppr Fittings, Plastic ppr pipe, plastic pipe, tube,pprct pipe, pprct fittings, Ppr Aluminum pipe, Ppr-Al-Ppr pipe, Ppr Fiber Pipe, Ppr Uv Pipe, Ppr perforated pipe, Ppr stop valve, Ppr Ball

Casting Metal / HDPE / Ppr Pipe Clamp Fittings Corrosion Resistant

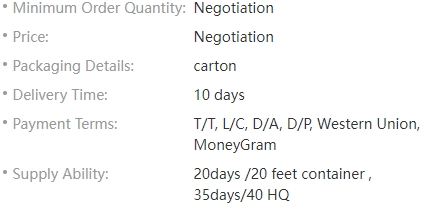

Payment & Shipping Terms

Description

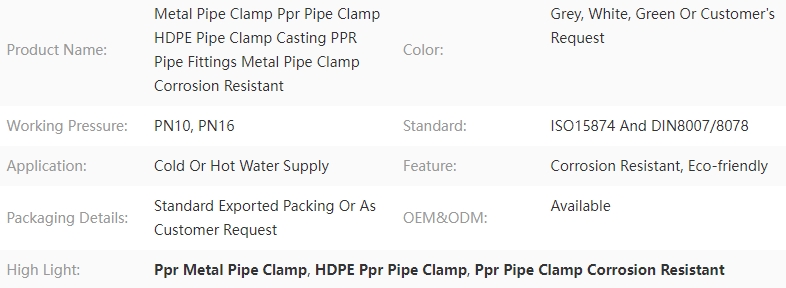

Metal Pipe Clamp Ppr Pipe Clamp HDPE Pipe Clamp Casting PPR Pipe Fittings Metal Pipe Clamp Corrosion Resistant

Ppr/HDPE Pipe Metal Clamp: Sizes: 20mm 25mm 32mm 40mm 50mm 63mm 75mm 90mm 110mm 125mm 140mm 160mm 200mm 250mm 315mm

PPR Pipe Fittings Low Foot Pipe Clamp ISO9001 DIN8077/8078 Colour OEM

Application:

1. Hot & cold water facilities for civil buildings, dwelling house,swimming pools,air port,hospital, hotel, office, school, marine facilities, etc.

Industrial pipe systems of food, chemical as well as electron, for instance.

deionized water

2. Drinking water supply

3. Air conditioning system

4. Pipe networks for solar energy facilities

5. Conveying systems for agriculture and gardens production

Features:

1. Hygienic, non - toxic: the product, green building materials, can be used for the piping system of pure drinking water.

2. Polypropylene-random (PP-R) water-supplying pipes and fittings from 20 to 160mm

3. Colors: white, grey, and other colors available upon requests

4. Long service life: under the prescriptive condition, the piping system can be used for more than 50 years.

5. Brass inserts (welding die) especially for PP-R from 20mm to 63mm available

6. PP-R pipe system related accessories available, including tools, clamps, and welding machines

| 1. High Temperature Resistance: the maximum sustained working temperature is up to 70 °C,the maximum transient temperature is up to 95°C | ||

| 2. Non-toxic: no heavy metal additives, would not be covered with dirt or contaminated by bacterium | ||

| 3. Corrosion Resistant: resist chemical matters or electron chemical corrosion | ||

| 4. Lower Installation Costs: light weight and ease of installation can reduce installation costs | ||

| 5. Higher Flow Capacity: smooth interior walls result in lower pressure loss and higher volume | ||

| 6. Long Life: more than 50 years under normal conditions more than 50 years under normal conditions | ||

| 7. Recycled and Environment-friendly | ||

Advantages

1) Lower total installed cost – Lightweight product is easier and faster to handle and install and less heavy equipment is required to lift and position pipe. This can result in reduced installation costs.

2) Easy to handle –PP and PP-R are lightweight products making handling and positioning pipe fittings easier and safer. Less heavy equipment is needed to unload, handle product on site and position into trenches.

3) Optimum hydraulic performance – PP-R’s smooth inner skin is resistant to build up and allows optimum hydraulic flow.

4) Chemical resistance – PP-R pipe fittings are resistant to corrosion by aggressive and saline soils and substances typically found in sewage effluent, including most industrial discharges.

5) Sensitive to the environment – The material-efficient production reduces the use of raw materials. PP and PP-R pipe fittings are long life products.

6) Flexibile – PP and PP-R are flexible pipe fittings which have the ability to cope with soil movement and external loading without cracking.

Application Field

Potable water pipe networks for cold and warm water installations of residential

buildings, hospitals, hotels, schools, office buildings and shipbuilding

Pipe networks for rainwater utilization systems

Pipe networks for compressed air plants

Pipe networks for swimming pool facilities

Pipe networks for solar plants

Pipe networks in agriculture and horticulture

Heating pipes for residential housing

Pipe networks for industry,

For Water Installations

|

Temperature |

Service life | Safety-factor=1.5 | |||

| SDR 11 | SDR 9 | SDR7.4 | SDR 6 | ||

| Nominal Pressere | |||||

| PN10 | PN12.5 | PN16 | PN20 | ||

| Permissible Working Pressure | |||||

| 20℃ | 1 | 15.0 | 18.9 | 23.8 | 30.0 |

| 10 | 13.7 | 17.3 | 21.7 | 27.2 | |

| 50 | 12.9 | 15.9 | 20.4 | 25.7 | |

| 40℃ | 1 | 10.8 | 13.6 | 17.1 | 21.2 |

| 10 | 9.2 | 12.4 | 16.0 | 20.2 | |

| 50 | 9.2 | 11.5 | 14.5 | 18.8 | |

|

50℃ |

1 | 9.2 | 10.8 | 14.5 | 18.3 |

| 10 | 8.2 | 10.5 | 13.1 | 16.5 | |

| 50 | 7.7 | 9.8 | 12.2 | 15.4 | |

| 60℃ | 1 | / | / | 12.2 | 15.4 |

| 10 | / | / | 11.0 | 13.8 | |

| 50 | / | / | 10.1 | 12.7 | |

| 75℃ | 1 | / | / | 9.9 | 12.3 |

| 10 | / | / | 7.5 | 9.3 | |

| 25 | / | / | 6.1 | 7.5 | |

SDR=Standard Dimension Ratio(diameter/wall thickness)

SDR=d/s(S=Pope series index from ISO 4065)

Production process

Automatic feeding → Handpiece feeding → Heating plasticization → Molding

↓

Ejection products ← Die sinking ← Cooling ← Pressurized molding ← Melting

↓

Edge finishing → Testing → Packing → Storage

Categories

- Plastic Ppr Pipe

- PPR Aluminum Pipe

- PPR Fiberglass Composite Pipe

- PPR Pipe Fittings

- PPR Double Union Ball Valve

- PPR Stop Valve

- Brass Insert

- Plastic Pipe Cutter

- PEX Tubing

- Brass Fittings

- Brass Compression Fittings

- Garden Hose Pipe Fittings

- Brass Flared Fittings

- PEX Brass Fittings

- Brass Ball Valve

- Brass Gate Valve

- Brass Bibcock

- Brass Angle Valve

- Brass Thermostatic Valve

- Water RO Purifier

Latest News

Contact Us

Contact: Kathy Zhang

Phone: 13361988316

Tel: +86 21 51316758

Add: No.80 Tian Gong Road Shanghai China

Johnsonyuan

Johnsonyuan