Brass Ball Valve

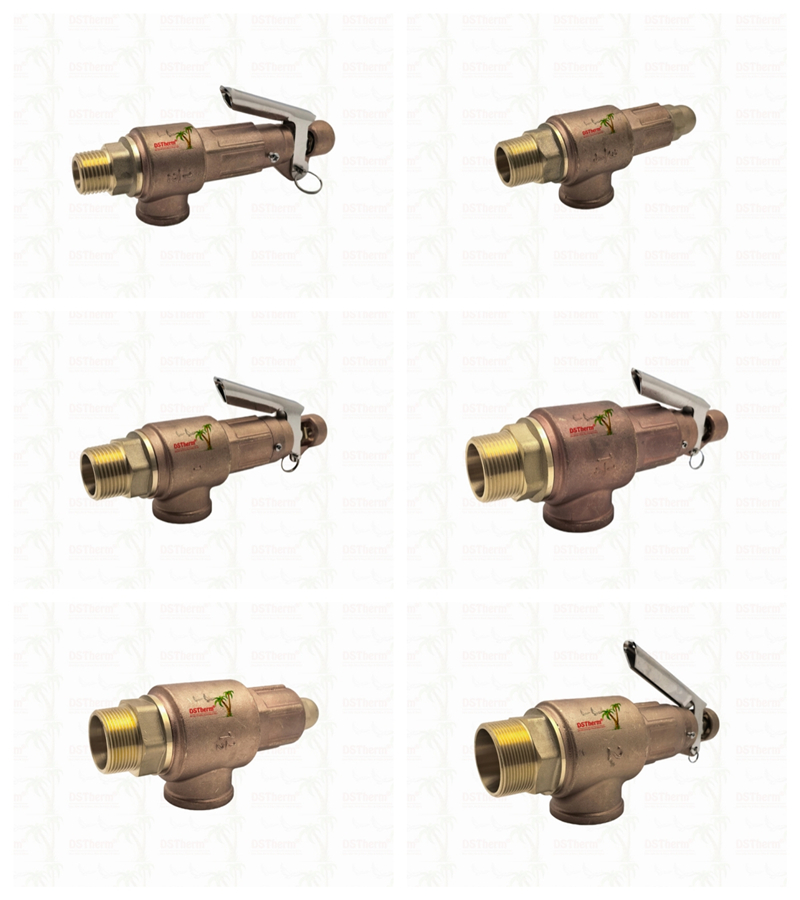

Brass Safety Valve 1/2"-2" Pipeline System Overpressure Protection Device Customized LOGO

- Place of Origin:Zhejiang China

- Brand Name:DSTHERM/OEM/CUSTOMIZED

- Certification:ISO9001/CW617N

- Model Number:1/2'-2'

- Product description: Ppr pipe, Ppr Fittings, Plastic ppr pipe, plastic pipe, tube,pprct pipe, pprct fittings, Ppr Aluminum pipe, Ppr-Al-Ppr pipe, Ppr Fiber Pipe, Ppr Uv Pipe, Ppr perforated pipe, Ppr stop valve, Ppr Ball

Brass Safety Valve 1/2"-2" Pipeline System Overpressure Protection Device Customized LOGO

Description

Specification

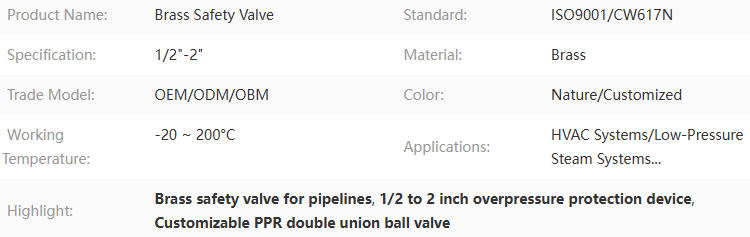

| Brass Safety Valve | Specification |

|

1/2" |

| 3/4" | |

| 1" | |

| 1-1/4" | |

| 1-1/2" | |

| 2" |

What is Safety Valve?

A safety valve is an automatic pressure relief safety device. Installed on pressure vessels, pipelines, or other pressurized equipment, it opens automatically when the internal system pressure exceeds a pre-set safety limit. This releases excess medium (gas, steam, or liquid) to the environment, preventing equipment explosion, damage, or personal injury caused by overpressure. It closes automatically once the pressure returns to normal.

Operating Principle

The operation of a safety valve is based on the principle of force balance. Its core component is a disc (or cartridge) held closed by a spring force.

- Normal Operation: The force exerted by the system pressure on the disc is less than the downward closing force from the spring, keeping the valve tightly sealed.

- Overpressure Condition: When system pressure rises to the preset opening pressure (set pressure), the force from the medium on the disc equals or slightly exceeds the spring force. The disc begins to lift, initiating release of the medium.

- Full-Flow Discharge: Pressure increases slightly further to the discharge pressure, causing the valve to open fully. The medium is discharged in large volume, leading to rapid pressure drop.

- Resealing: As the medium discharges, system pressure falls to the reseating pressure. The spring force again exceeds the medium force, causing the disc to return and reclose the valve.

Precautions

- Regular Calibration: Safety valves must undergo periodic calibration by a certified agency (typically at least annually) to ensure accurate set pressure and reliable operation.

- No Unauthorized Adjustment: Users are strictly prohibited from adjusting the spring or other components to alter the set pressure.

- Proper Selection: The correct type, size, and material of the safety valve must be selected based on the protected equipment's process conditions (medium, temperature, pressure, required capacity).

- Routine Inspection: Regular checks are required for leaks, corrosion, and the integrity of the lead seal.

Applications For Brass Safety Valve:

- HVAC Systems: Safety relief for heating boilers, AC units, and solar water heating systems.

- Compressed Air Systems: Protection for air compressors, air receivers, and drying equipment.

- General Industrial Equipment: Used with small pressure vessels, hydraulic presses, pump discharges, and dead-end pipe sections.

- Low-Pressure Steam Systems: Suitable for small steam generators, steam tracing lines, etc. (Note temperature limits).

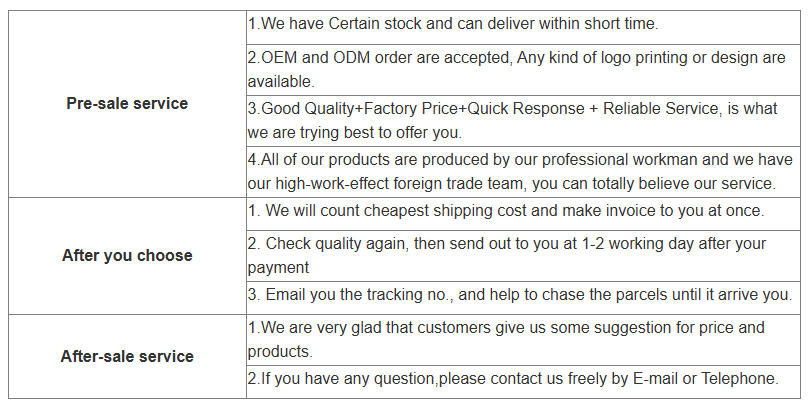

We will be your better choice!

Categories

- Plastic Ppr Pipe

- PPR Aluminum Pipe

- PPR Fiberglass Composite Pipe

- PPR Pipe Fittings

- PPR Double Union Ball Valve

- PPR Stop Valve

- Brass Insert

- Plastic Pipe Cutter

- PEX Tubing

- Brass Fittings

- Brass Compression Fittings

- Garden Hose Pipe Fittings

- Brass Flared Fittings

- PEX Brass Fittings

- Brass Ball Valve

- Brass Gate Valve

- Brass Bibcock

- Brass Angle Valve

- Brass Thermostatic Valve

- Water RO Purifier

Latest News

Contact Us

Contact: Kathy Zhang

Phone: 13361988316

Tel: +86 21 51316758

Add: No.80 Tian Gong Road Shanghai China

Johnsonyuan

Johnsonyuan